Vertical Mill

Product Introduction

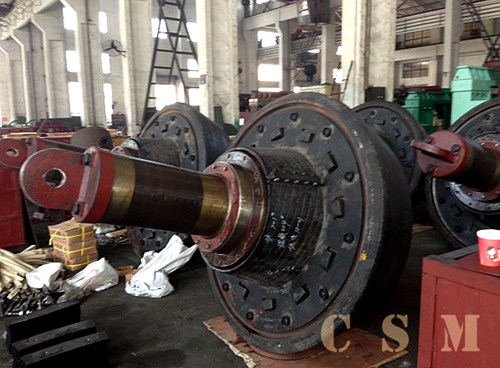

Our vertical mill is a member of the roller mills. As requested, it can be equipped with 2-4 rollers, each of which is a power unit that is composed of fixed rocker arm, stand for installing the rocker arm, and hydraulic system. This power unit is an integral or standard component of the vertical roller type mill. It can be arranged around the grinding table by two rollers, three rollers or four rollers.

Working Principle

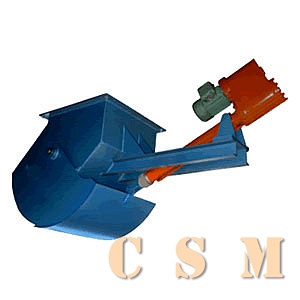

Firstly, raw materials are fed into feed tube by rotary feeder. The feed tube can reach the inner part of the grinding mill along separator side or through its center part. Under the effect of gravity and air flow impact, the materials will fall on to the grinding table center. The grinding table, firmly connected with a reducer, rotates at a constant speed, which can uniformly distribute the materials on the liner plate at the horizontal direction where the inclined rollers will grip and pulverize the materials. Owing to the hydraulic system, grinding is conducted under the force of pressure and friction.

When the grinding table revolves, it will generate centrifugal force which will throw the crushed materials to the edge. The materials off the table will rise up along with the hot air flow circularly blown into the mill and then enter the separator thought middle mill shell. During this process, complete heat transfer between the materials and the hot gas can be implemented. Thereby the moisture will be quickly evaporated to remain only 1%. After entering the separator, those materials that are not crushed to required standard will be separated out and sent into the mill for grinding again. In addition, separated materials will be carried into bag filter by the air flow generated by the circulating fan for dust collecting.

Features

The vertical mill is remarkably characterized by low noise, low unit energy consumption, strong adaptability, easy adjustment and maintenance, as well as rapid control response. From startup to shut down, it will generate quite small vibration. In addition, this type of powder grinding machinery boasts excellent dry process grinding ability and can be used to grind a wide range of materials. User friendly design makes this equipment occupy small space and wear-out parts can be replaced with no need to dismantle the mill.